As the COVID-19 pandemic continues on, weaknesses in global medical devices supply chains have become apparent. Hospitals everywhere are struggling to maintain adequate numbers of ventilators, devices which precisely time the flow of compressed oxygen into a patient with lungs weakened by viral pneumonia in order to extend life and allow time for the body to clear the infection.

As the COVID-19 pandemic continues on, weaknesses in global medical devices supply chains have become apparent. Hospitals everywhere are struggling to maintain adequate numbers of ventilators, devices which precisely time the flow of compressed oxygen into a patient with lungs weakened by viral pneumonia in order to extend life and allow time for the body to clear the infection.

Groups all over the world are working hard to provide an alternative supply of ventilators for use in treating COVID-19 patients. The work is often done with freely shared plans and open-source software—no effort is made to earn a profit. The goal is to quickly deploy these devices where they are needed, using parts freely available online and in local hardware stores.

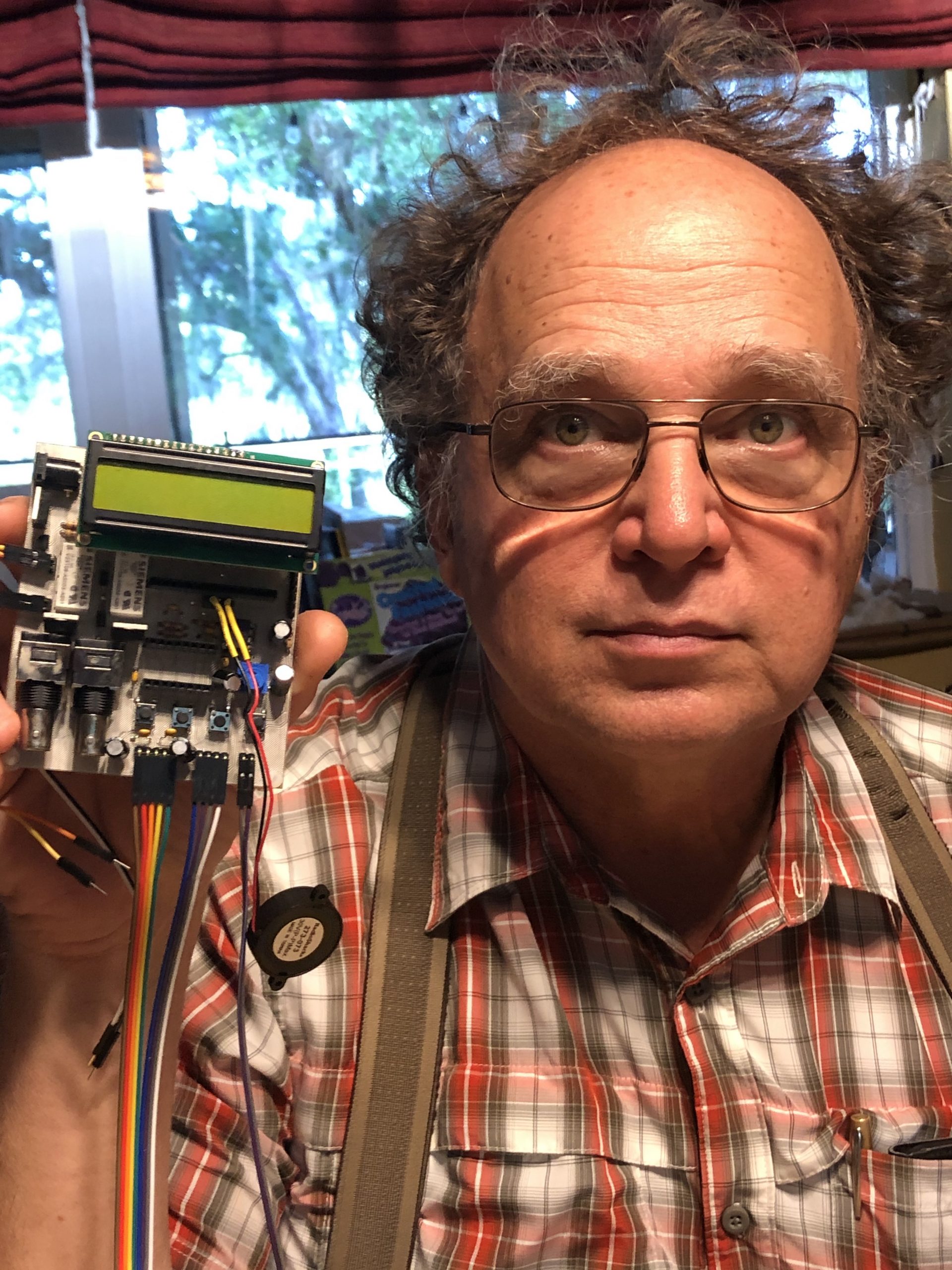

The Gainesville Sun reports that many UF engineers are working collaboratively on an open-source ventilator design project. Among them are Gordon Gibby, M.D., an electrical engineer and recently retired associate professor of anesthesiology at UF; and Samsun Lampotang, UF professor of anesthesiology. As the Sun details, Lampotang had long ago helped respiratory therapist colleagues build a minimal-transport ventilator as an MAE student. He was inspired to build a low-cost, open source prototype of a ventilator. He contacted Dr. Gibby for assistance, and despite some initial skepticism, Gibby realized the project had potential.

The Gainesville Sun reports that many UF engineers are working collaboratively on an open-source ventilator design project. Among them are Gordon Gibby, M.D., an electrical engineer and recently retired associate professor of anesthesiology at UF; and Samsun Lampotang, UF professor of anesthesiology. As the Sun details, Lampotang had long ago helped respiratory therapist colleagues build a minimal-transport ventilator as an MAE student. He was inspired to build a low-cost, open source prototype of a ventilator. He contacted Dr. Gibby for assistance, and despite some initial skepticism, Gibby realized the project had potential.

“I saw what they were doing, and realized it was going to work!!!!” Gibby wrote in an email to fellow members of ARRL, the national amateur radio (known as Ham radio) association.

ECE Florida staff engineer (and Ham radio enthusiast) Mike Stapleton is helping with these efforts. Working with a group of online volunteers, he has contributed some design modifications, creating a through-hole circuit board design which is easier to solder and incorporates a display and speaker. Work continues on design and code modifications, and safety and legal considerations are being considered, but the hope is to soon have a safe and durable design that is ready for production. Stapleton’s colleague Eric Liebner, also a staff engineer, is beginning work on the enclosure for the device using the department laser cutter.

Further information is available at the Department of Anesthesiology website.