Many of us know intuitively that computer chips are (by necessity) getting smaller and more and more complex. And the news is filled with dire stories detailing worldwide supply chain issues or chip shortages and their wide-ranging economic effects. ECE Assistant Professor Navid Asadi reminds us of another issue with modern chips—physical assurance. Put another way, how can we be sure that the chips inside our devices are safe, reliable, and will perform as they were designed? As the bulk of chips are fabricated outside the purview of the U.S., these questions are even more critical in a national security sense. A chip deployed in a military aircraft or a power plant must not only work perfectly, but must be free of Trojans, spyware, or deliberate sabotage. Worried? So is Dr. Asadi. But luckily, his team is working diligently, leveraging AI/machine learning and the advanced physics of imaging and characterization to develop increasingly complex tools to enable physical assurance of modern chips—making sure that the final product is exactly what the chip designer intended. Utilizing the AI supercomputing infrastructure at the University of Florida as well as the expertise which led to his receipt of an NSF CAREER Award, Dr. Asadi has emerged as a worldwide leader in the area of physical assurance for integrated circuits (ICs).

A Room In A City

Dr. Asadi visualizes a modern chip as a structure as complex as the entire city of San Francisco—billions upon billions of transistors, layer upon layer. Trying to find a malicious component or a point of failure inside the chip is analogous to locating one room in one building in the city. In other words, nearly impossible, at least without the aid of technology. Rather than have a human examine the components piecemeal, researchers leverage AI and machine learning to analyze vast datasets from the manufactured chips, looking for errors and anomalies which are indicative of malicious sabotage or espionage, or defects in manufacturing.

The Right Tool for the Job

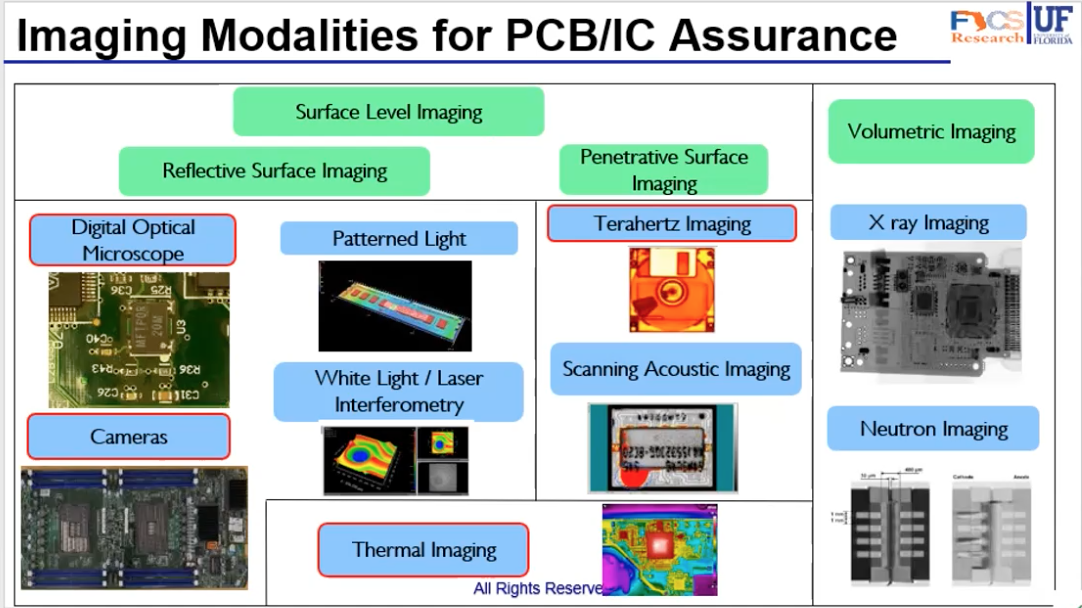

To find the metaphorical room in the city, researchers use a variety of modalities to examine and extract data from the chips. Though some modalities require the chip to be partially damaged (a process called sample preparation), many of the modalities allow the examination of the chips while keeping them intact.  As the image below illustrates, these modalities vary wildly. Each creates a unique (and massive) dataset. The question becomes: how to ingest the data and make it meaningful? The answer? Artificial intelligence. Using AI/machine learning, researchers can automate the comparison of the datasets from the manufactured chips with known, ‘golden’ sets of data (if available), enabling a ‘good’ or ‘bad’ determination. In effect, his team is training computers to locate that single room in the city, automatically and efficiently. The overall goal for this work is rapid, efficient, accurate, and automated verification of a manufactured chip’s authenticity.

As the image below illustrates, these modalities vary wildly. Each creates a unique (and massive) dataset. The question becomes: how to ingest the data and make it meaningful? The answer? Artificial intelligence. Using AI/machine learning, researchers can automate the comparison of the datasets from the manufactured chips with known, ‘golden’ sets of data (if available), enabling a ‘good’ or ‘bad’ determination. In effect, his team is training computers to locate that single room in the city, automatically and efficiently. The overall goal for this work is rapid, efficient, accurate, and automated verification of a manufactured chip’s authenticity.

As with any work in this area, of course, the process is only as good as the underlying data. Towards this end, researchers at the Florida Institute for Cybersecurity (FICS) Research work with the hardware security community to pool resources and datasets in public resources like TrustHub to enable researchers around the world to develop the efficient AI models which will yield the fastest validation techniques.

A Worldwide Issue

The challenges associated with physical assurance are massive and have major repercussions on the global economy. As the ‘Big Hack‘ reminded the world, so much of the global economy relies upon trust—the ability to fundamentally trust that a product is what it purports to be. As Dr. Asadi meets with colleagues at conferences around the world, he hears a common refrain: this is a huge problem and which doesn’t get nearly enough attention or resources. Dr. Asadi understands why.

Until about five years ago, there were very limited resources to develop security primitives for electronics. And even now, people are still not fully aware of the risks. For example, let’s say a company offers an electronic system, say a refrigerator, that costs $2,000 and a competitor give you the exact same fridge for $50 more, but it’s really secure. How many people are going to choose the secure one? It’s unfortunately human nature to take the cheaper one until there is an obvious, catastrophic problem happening.

Dr. Navid Asadi is an assistant professor in the Department of Electrical & Computer Engineering. He also serves as co-director of the SCAN Lab at the Florida Institute for Cybersecurity (FICS) Research and associate director of the Micro-Electronics Security Training (MEST) Center. He recently received an NSF CAREER Award in support of his project, “Backside Protection Against Contactless Optical Attacks on Integrated Circuits in Advanced Technology Nodes.”

His physical assurance YouTube channel features educational videos on the topic including: advanced packaging, imaging, and characterization.